What is Robust Quality Engineering(RQE)?

Overview:

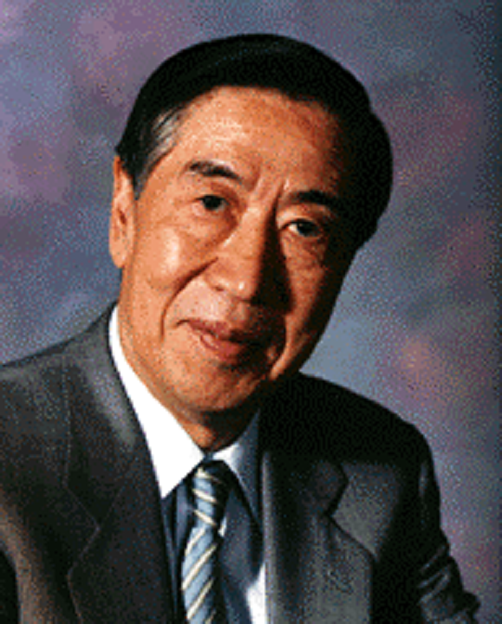

Robust Quality Engineering is a discipline proposed by Dr. Genichi Taguchi.

The method of design of experiments in factories was applied to many problems by Dr. Taguchi and others, and contributed to the improvement of the quality of industrial products in Japan. Since then, Dr. Taguchi has continued to apply the excellent theory he developed to a number of problems, including today’s “Robust Quality Engineering”.

Dr. Taguchi has since developed a number of methodologies, including today‘s quality engineering. In particular, “Robust Quality Engineering," which improves efficiency by systematizing the conventional trial-and-error R&D process, is unique in the world and is highly regarded by many researchers and engineers.

Dr. Taguchi - From Design of Experiments to Robust Quality Engineering

In 1980, at AT&T Bell Labs, Dr. Taguchi said

“Whack-a-mole after whack-a-mole after whack-a-mole will not lead to essential solutions.”

“If you don't design it right at the design stage, you'll never get out of trouble.”

・Bell Labs' microprocessor production - which halved the variation in the photolithography process of drilling 230,000 2-μm-diameter holes in a 1.5-cm square - resulted in cutting production time in half.

・The results were published in the Bell System Technical Journal and caused a great sensation, and subsequently contributed greatly to major American industries, including Ford Motor Company.

・After this, Dr. Don Clausing visited Xerox Corporation and named it the “Taguchi Method”.

In his later years, Dr. Taguchi was said to have said, 'The work I have done can be summed up in two things.

1.Making orthogonal tables easier to use.

2.The addition of data acquisition and analysis methods to the design of experiment method to reduce variation in function.